Sensor Modifications

Below you will find a list of explanations of the different options for sensor modifications. Please note that most of these options will be a trade-off with other sensor characteristics (see below). Also, most sensor modifications will add extra cost to the price. Read more...

Explanations of sensor modifications

Fast response

The normal response time of the smallest microsensors is around 1-3 seconds but for some experiments, e.g. photosynthesis measurements, it may be an advantage to have an even faster response time. We can make sensors with response times down to 0.2-0.3 seconds.

Low stirring sensitivity

The standard stirring sensitivity of our sensors is 2% but in some delicate systems you may require the sensor to be even less sensitive than that. We can produce sensors with stirring sensitivities down to 0.5%.

High signal

The maximum signal is different for each sensor and will depend on several parameters. If you require a high sensitivity (high resolution) of the signal, sensors can be customized with a high maximum signal.

Shaft length

For some set-ups, an extended shaft length of the sensor is an advantage. This may be to allow room for more sensors or more auxiliary equipment.

Tip length

Some systems are so tiny that even the standard tip length, i.e. the length of the thin part of the microsensor, is too short. This problem can be solved using customized sensors with a more slender design.

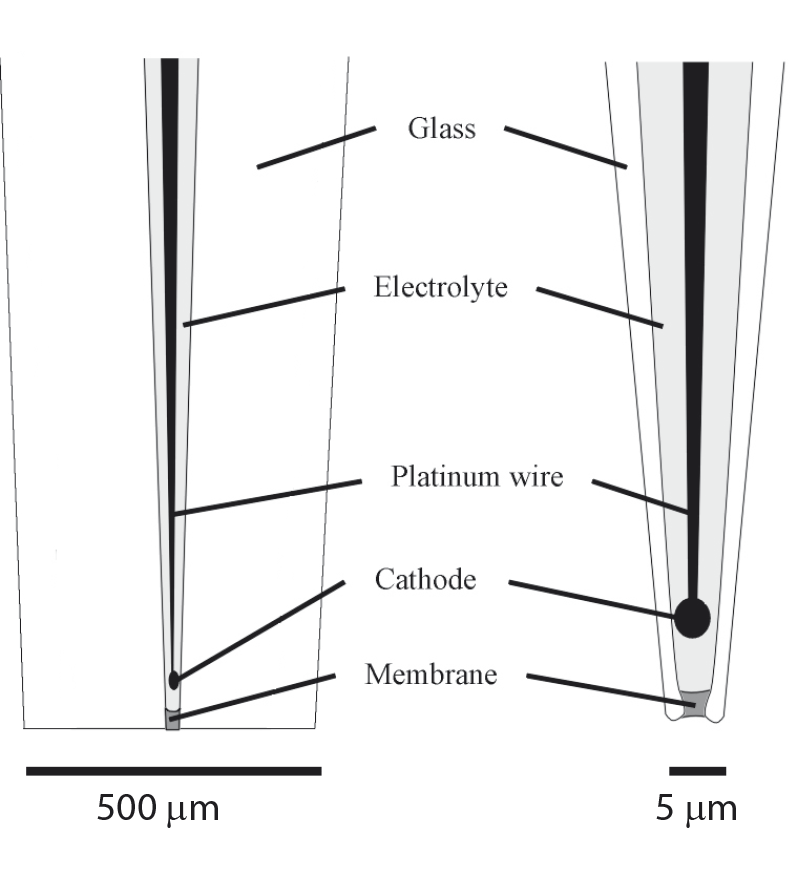

Tip diameter <10 µm

Our smallest standard sensor is 10 µm but we can make oxygen sensors down to 2-3 µm for specific measurements.

High temperature tolerance

Adding organic electrolyte in some sensors will increase the temperature tolerance up to around 100 °C.

Theory on response time, stirring sensitivity, and signal-to-noise ratio of oxygen sensors

There is a relationship between response time, stirring sensitivity and signal to noise ratio of an oxygen sensor.

Modelling shows that for an ideal sensor, the stirring sensitivity can be approximated by R/4L, where R = radius of the hole in the sensor tip and L = distance from the tip to the cathode.

The response time is proportional to L squared (L2). Thus a fast responding sensor has a very small L.

In order to reduce the relative noise (= low noise to signal ratio, high signal to noise ratio) a large signal is an advantage. A large signal also offers better resolution of the measurement. The signal is proportional (rough calculation) to R2/L (R squared divided with L). Thus sensors with a large R and a small L give the highest signal to noise ratio.

Examples:

- A sensor with a fast response and a low stirring sensitivity must have a small signal.

- A sensor with a fast response and a large signal will must have a higher stirring sensitivity.

For general use we can make sensors with a stirring sensitivity of <2% and a response time of <3 s, which is a good solution for most users.

Quick Enquiry

Related products

High performance oxygen microsensor

Optical oxygen sensor technology

Detect hydrogen sulfide in your sample

Highly sensitive hydrogen microsensor for gas and liquid measurements

Measure dissolved and gaseous nitrous oxide

Measure minute concentrations of nitric oxide

Miniaturized pH electrode

Measure redox potential in microenvironments

Microelectrode to measure electric potential

Reference electrode for pH or Redox microelectrodes

Monitor temperature in your sample

Measure ultra low oxygen concentrations (<10nM)

Ready to get started?

Contact us today to discuss whether microsensors are the right choice for your research application.