Nitrogen Removal in wastewater

Nitrogen removal via nitrite has gained increasing attention due to its potential cost savings. Membrane aerated biofilm reactors (MABRs) are one potential technology suitable to achieve nitritation. In this study, Lackner et al (2010) compared lab scale MABRs (counter-diffusion) with conventional (co-diffusion) biofilm reactors to evaluate the influence of environmental conditions and operational parameters on nitritation performance. Oxygen mass transfer rates are postulated as a crucial parameter to control nitration in the MABR.

Experimental setup

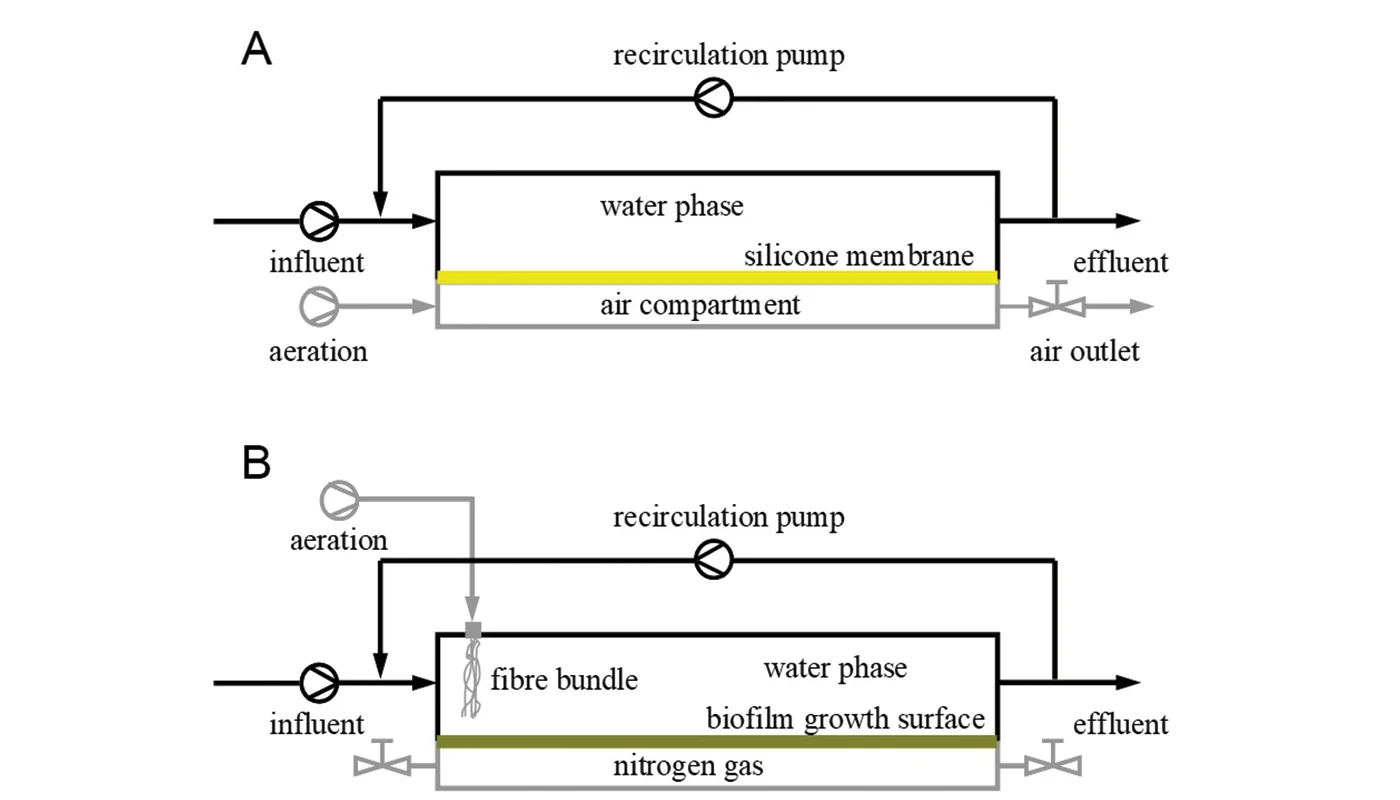

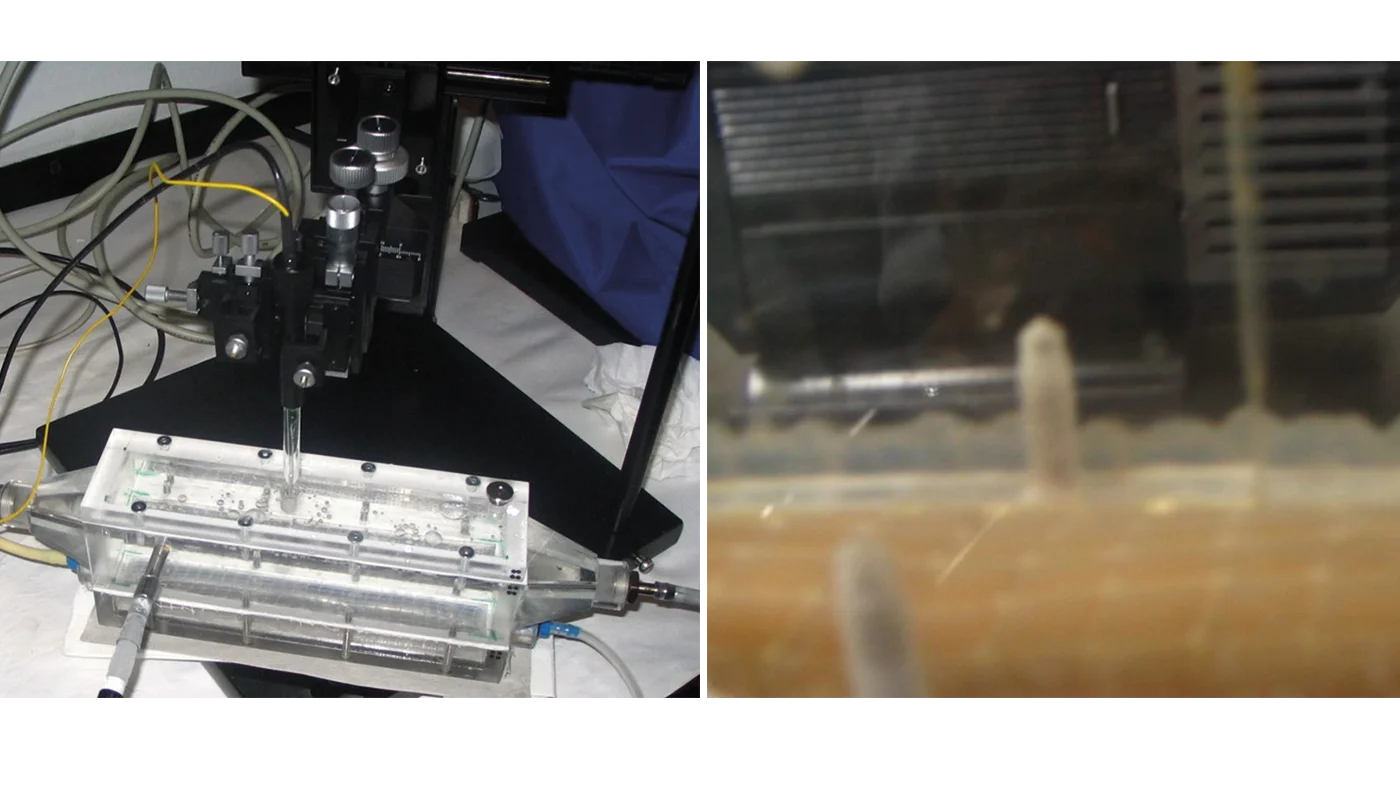

Four reactor systems were operated for growth and in situ inspection of co- and counter-diffusion biofilms. The liquid phase compartment was separated from the gas compartment by a flat sheet silicone membrane which also served as the growth surface for the biofilm. The counterdiffusion biofilm (Fig. 1A) reactors were aerated by providing constant air flow through the gas compartment allowing oxygen to diffuse through the flat sheet silicone membrane into the base of the biofilm. In the co-diffusion (Fig. 1B) reactors the air compartment was flushed with N2 gas and sealed to prevent oxygen from entering the system through the bottom of the biofilm.

Aeration was provided in the bulk liquid. The reactor systems were operated under similar conditions with the aim to achieve partial nitrification for subsequent Anammox inoculation. Feed was composed of a synthetic wastewater leading ammonium-N concentration of 200 g NH4-N m-3.

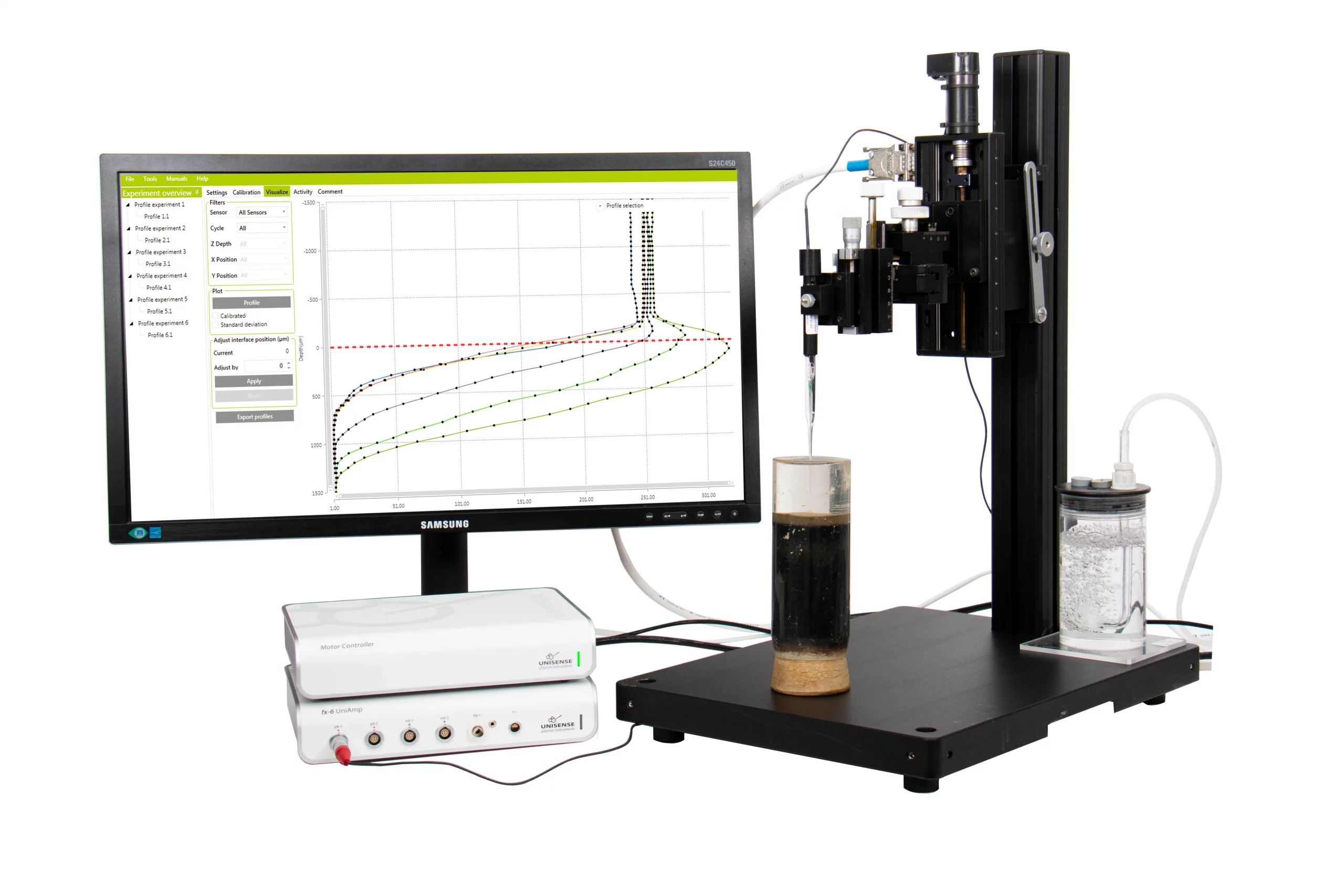

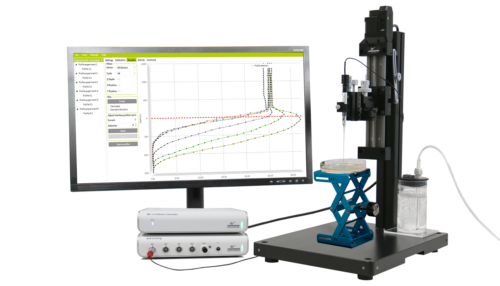

Oxygen microsensor measurements in the biofilms were conducted with a 10 µm Clarktype oxygen microsensor (OX10, Unisense A/S). The sensor was inserted directly into the biofilm from the bulk liquid through a small hole in the reactor lid for in-situ profiling using the Unisense MicroProfiling System (Figure 3).

Results and conclusions

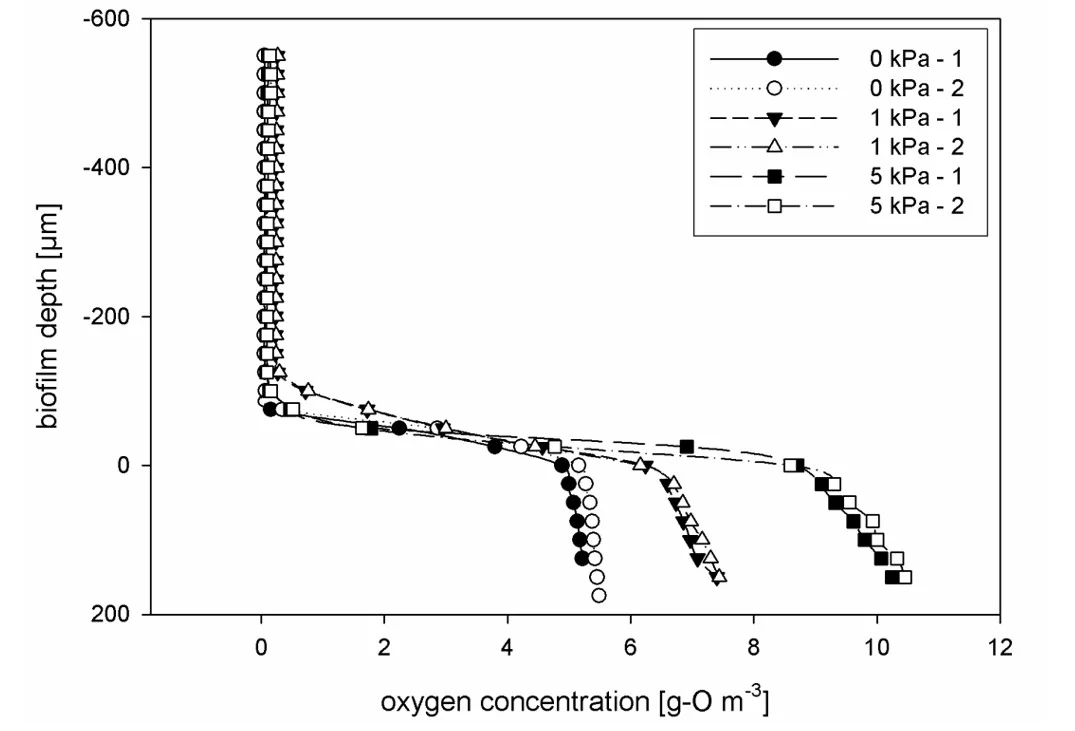

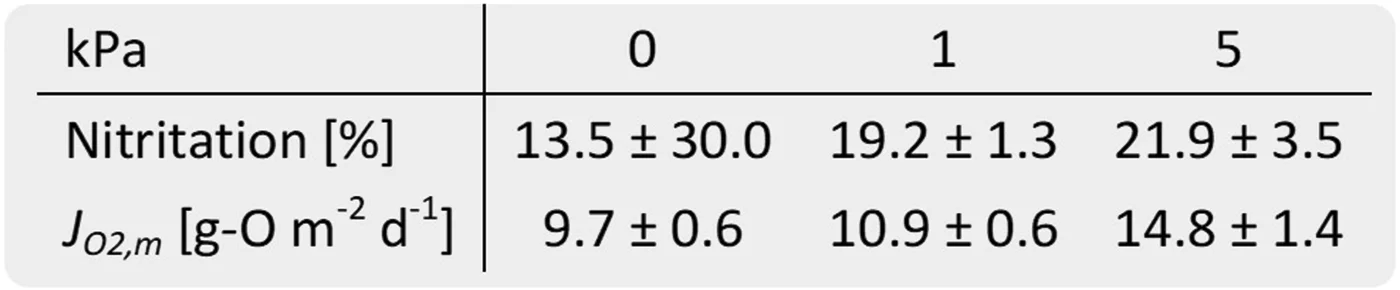

The nitritation efficiencies in the Counter diffusion biofilm did not vary significantly for the applied pressure range even though oxygen concentrations at the membrane base and oxygen fluxes were different. Examples of typical profiles at the different pressures are shown in Figure 4 with the respective fluxes and nitritation efficiencies (Table 1).

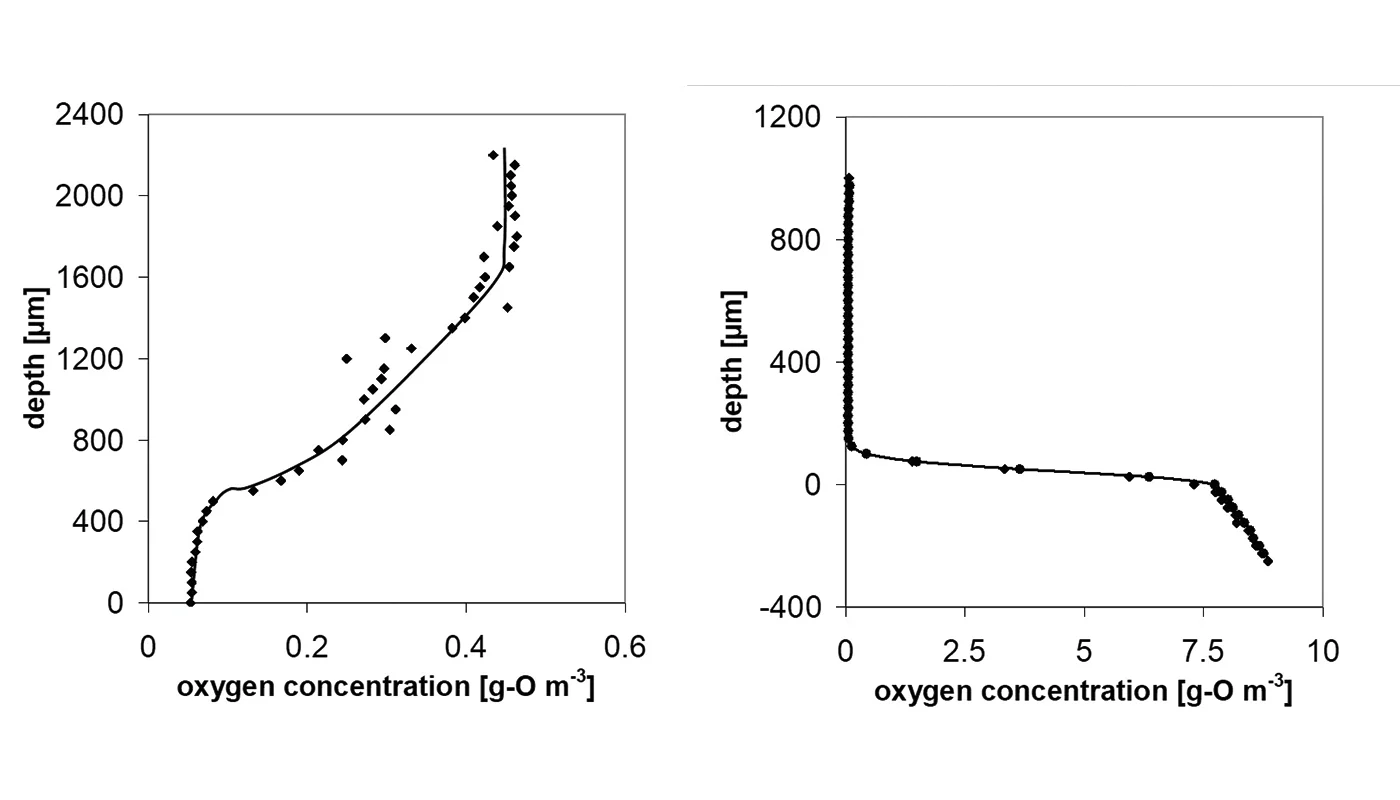

Oxygen profiles in the different biofilm geometries are shown in Figure 5. The oxygen penetration depth in the counter-diffusion system (Fig. 5, right) was approximately 125 µm in all profiles with a biofilm thickness estimated between 650-800 µm. Oxygen concentrations at the biofilm membrane interface were above 5 g-O m-3 in all experiments.

The profile of the co-diffusion system (Fig. 5, left) revealed a less steep oxygen gradient in the biofilm (oxygen penetration depth of 300-400 µm). Biofilm thickness was approximated to 600-800 µm and the oxygen concentration in the bulk liquid was between 0.4-0.8 g-O m-3

This study demonstrated the challenges in achieving nitritation in MABRs and the importance of careful determination, adjustment, and monitoring of oxygen and ammonium fluxes and their respective absolute concentrations. Further research should focus on finding the optimal biofilm thickness and oxygen penetration depth for nitritation MABRs taking into account the impact of absolute concentrations of oxygen and the nitrogen species.

Related Publications

Related Products

High performance oxygen microsensor

UniAmp Multi Channel for all Unisense sensors and electrodes including optical sensors

Microprofiles with extreme accuracy, high spatial and temporal resolution

Water resistant Field MicroProfiling System to generate, study, and analyze microprofiles

Optical oxygen sensor technology

Detect hydrogen sulfide in your sample

Economic amplifier portfolio for single analytes - O2, pH/mV, H2, N2O or H2S

Measure dissolved and gaseous hydrogen with a high-precision

Optode meter for accurate quantification

Measure dissolved and gaseous nitrous oxide

Measure minute concentrations of nitric oxide

Miniaturized pH electrode

Measure redox potential in microenvironments

Microelectrode to measure electric potential

Reference electrode for pH or Redox microelectrodes