Hydrogen Sensor Measurement Principles and Applications in Research

Hydrogen sensors are used to measure hydrogen (H2) in both liquid and gas environments. At Unisense, we develop Clark-type hydrogen sensors for advanced research and renewable energy applications, where precise, real-time hydrogen measurement is essential.

Our hydrogen sensors are used in applications such as photocatalytic and photoelectrochemical water splitting, green electrolysis, biomethanation, CO2 conversion, artificial photosynthesis, and other renewable energy and biological systems. Our sensors are used by universities and companies worldwide and have contributed to thousands of peer-reviewed publications.

Measuring Principle of the Hydrogen Sensor

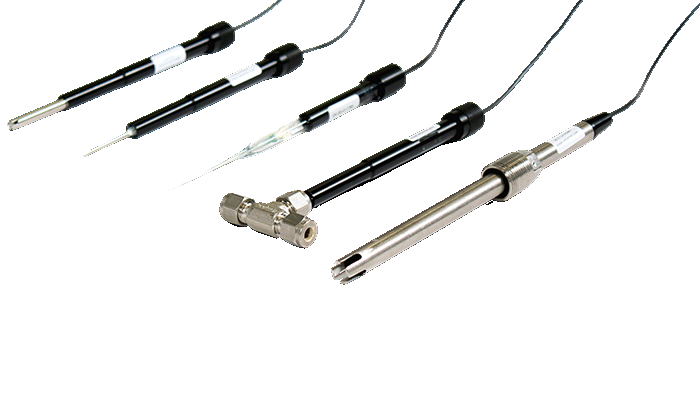

The Unisense hydrogen sensor is a Clark-type amperometric sensor. The sensor measures partial pressure, not concentration. Because it measures partial pressure, the same hydrogen sensor can be used to measure hydrogen in both the liquid and gas phase.

The hydrogen sensor operates according to an electrochemical working principle:

- The outer tapered glass tip is equipped with a silicone membrane.

- The membrane separates the internal electrochemistry from the sample.

- Hydrogen diffuses through the silicone membrane.

- At the positively polarized platinum working electrode, hydrogen is oxidized.

- Electrons are delivered to the reference electrode where reduction takes place.

- The generated current is proportional to the hydrogen level outside the membrane.

The resulting signal is in the picoampere (pA) range and requires a high-quality amplifier for accurate measurement.

Partial Pressure Measurement in Gas and Liquid

Because the hydrogen sensor measures partial pressure rather than concentration, it can operate in both gas and liquid systems. Hydrogen diffuses through the membrane regardless of whether it is present in a gas phase or dissolved in a liquid. This makes the hydrogen sensor suitable for:

- Closed cuvettes

- Flow systems

- Bioreactors

- Inline reactor setups

The sensing occurs at the tip of the sensor, enabling localized measurements and spatial profiling.

Advantages of the Hydrogen Sensor

The measuring principle gives the hydrogen sensor several advantages:

- Measurement of hydrogen in liquid and gas phase

- Fast response time

- Ultrasensitive detection

- Flow-independent measurements in liquid systems

- Different mounting options

- Inline and in situ measurements

- Suitable for high-pressure systems

- Cost-effective alternative to techniques such as gas chromatography (GC)

Because the sensors are handmade, response time and sensitivity can be customized by changing the tip dimensions.

The cost-effective nature of the H2 sensor makes it possible to use multiple sensors simultaneously in the same setup to obtain spatially resolved hydrogen measurements.

Technical Specifications

Temperature range: 0–60 °C

Pressure tolerance: Up to 20 bar (standard range)

Response time (T90): < 15 seconds | Optional: < 0.3 seconds for 10-100 µm tip sizes

Humidity: 0–100%

Measurement ranges: Low range | Standard range | High range

Detection limits and measurement ranges vary depending on the selected sensor type

Hydrogen Sensor Applications in Renewable Energy and Reactor Systems

The hydrogen sensor is widely used in renewable energy research and reactor-based systems.

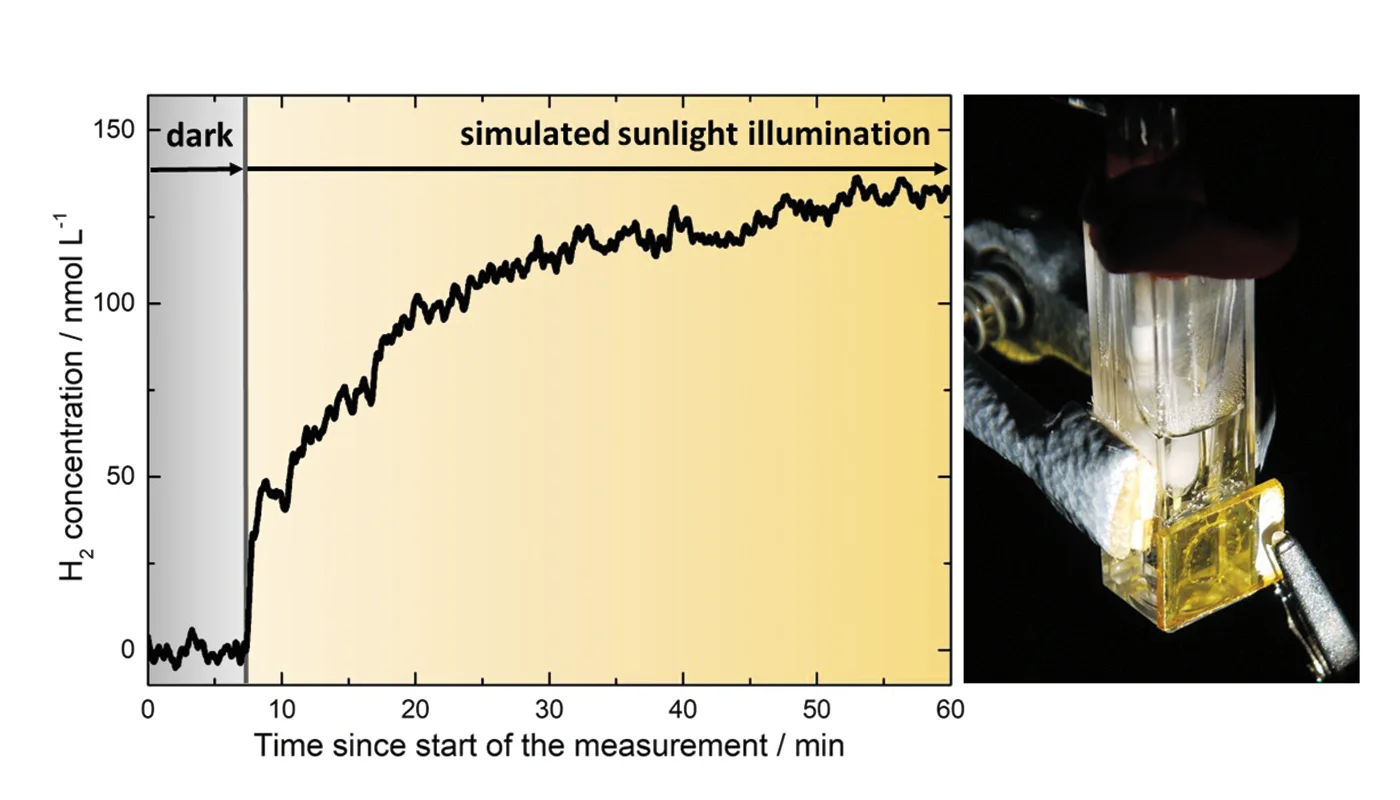

Photoelectrochemical Water Splitting

In studies of novel photoelectrodes, the hydrogen sensor has been used to measure modest hydrogen production in small volumes during illumination experiments. Continuous monitoring confirmed stable hydrogen evolution, where ultrasensitive detection was essential.

Sick, Torben, et al. "Oriented films of conjugated 2D covalent organic frameworks as photocathodes for water splitting." Journal of the American Chemical Society 140.6 (2017): 2085-2092

Monitoring Biomethanation in Trickle Bed Reactors

In biomethanation systems converting CO2 and H2 into methane, multiple inline hydrogen sensors have been used to monitor hydrogen at different reactor positions. By inserting hydrogen sensors at inlet, middle, and outlet positions:

- Hydrogen gradients were identified.

- Spatial hydrogen consumption could be resolved.

- Early warning of process deterioration was obtained days before traditional GC measurements.

Monitoring was performed over extended periods, demonstrating long-term stability and real-time control possibilities.

Sieborg, Mads et al. "Enhanced process control of trickle-bed reactors for biomethanation by vertical profiling directed by hydrogen microsensor monitoring." Bioresource Technology 384 (2023): 129242.

CO2 Conversion in Bioelectrochemical Systems

In bioelectrochemical CO2 conversion systems, hydrogen, oxygen, and CO2 are fed to microorganisms to produce organic compounds. Inline hydrogen measurement enabled:

- Monitoring of correct feed ratios

- Identification of process limitations

- Monitoring of explosion safety

- Real-time correlation with bacterial growth and product formation

The hydrogen sensor allowed dissolved H2 levels to be measured inline in real time.

Schoenmakers, Pierre, et al. "Isopropanol production from carbon dioxide by Cupriavidus necator using a zero-gap cell with culture broth as catholyte." iScience (2025)

Hydrogen Production from Artificial Enzymes

In research on sustainable hydrogen production using molecular catalysts based on Earth-abundant elements, the hydrogen sensor has been used to quantify hydrogen production in small volumes.

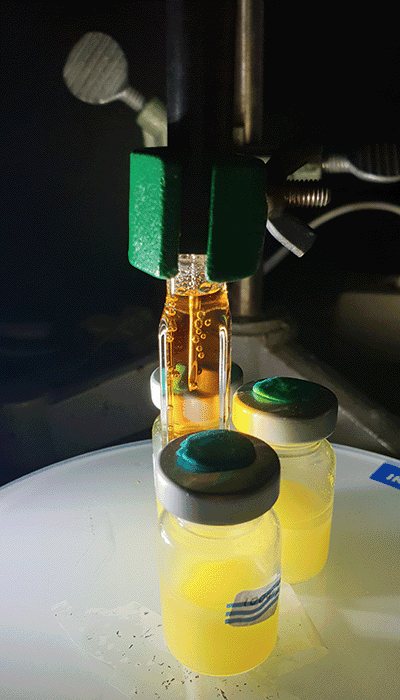

In one study, researchers engineered a novel enzyme to stabilize a cobaloxime catalyst and measured photocatalytic hydrogen production in solution. The hydrogen sensor was inserted into closed cuvettes, enabling real-time, ultrasensitive hydrogen quantification.

This approach allowed straightforward hydrogen measurement during electrochemical and light-induced water splitting experiments in small-volume systems. You can learn more in our application note: Hydrogen Production by a Fully De Novo Enzyme.

Berglund, Sigrid, et al. "Hydrogen production by a fully de novo enzyme." Dalton Transactions 53.31 (2024): 12905-12916.

Thermochemical Water Splitting Cycles

In thermochemical cycles for hydrogen production, inline hydrogen sensors mounted in flow cells were used to monitor hydrogen production during repeated cycles.

Hydrogen production performance across cycles could be evaluated, supporting optimization of material performance and process stability.

Torre, Francesco, et al. "Effect of atomic substitution on the sodium manganese ferrite thermochemical cycle for hydrogen production." Materials Today Energy 29 (2022): 101094.

Summary

The Unisense hydrogen sensor enables:

- Measurement of hydrogen in liquid and gas phase

- Real-time measurements (< 15 s response time)

- Ultrasensitive detection or oversaturation measurements

- Flexible and cost-effective setups for renewable energy research

By combining partial pressure measurement, microscale sensing, and inline integration possibilities, the hydrogen sensor supports advanced research and industrial R&D applications requiring precise hydrogen measurement.

If you want to learn more about the H2 sensor, you can watch the recording of our webinar: Hydrogen in Renewable Energy Research.