Inline Hydrogen Monitoring in Reactor and Renewable Energy Systems

Hydrogen measurement plays a central role in renewable energy research and reactor-based hydrogen production systems. In Power-to-X applications, green electricity is converted into other energy carriers using hydrogen from water splitting or electrochemical processes.

Unisense hydrogen sensors are used in research areas including:

- Photocatalytic and photoelectrochemical water splitting

- Green electrolysis

- Biomethanation

- CO₂ conversion

- Artificial photosynthesis

- Novel and advanced hydrogen production

- Biological systems

Accurate hydrogen measurement enables researchers and engineers to understand process dynamics, optimize performance, and monitor system stability in both laboratory and pilot-scale environments.

Inline Hydrogen Monitoring in Reactor Systems

Traditional reactor monitoring methods often treat systems as “black boxes,” limiting insight into internal hydrogen gradients and consumption patterns.

In biomethanation systems converting CO2 and H2 into methane, multiple inline hydrogen sensors have been installed at different vertical positions within trickle bed reactors.

This setup enabled:

- Identification of hydrogen gradients throughout the reactor

- Spatially resolved hydrogen consumption profiles

- Early warning of process deterioration days before conventional GC measurements.

Hydrogen monitoring was performed over extended periods, including 135 days of operation, demonstrating long-term stability and the value of real-time measurement in process control.

Monitoring CO2 Conversion in Bioelectrochemical Systems

In bioelectrochemical systems producing compounds such as isopropanol from CO2, hydrogen measurement supports safe and optimized operation.

Hydrogen, oxygen, and CO2 are supplied to microorganisms, and inline hydrogen measurement enables:

- Monitoring of correct gas feed ratios

- Identification of process limitations

- Monitoring of explosion safety risks

- Real-time correlation between hydrogen consumption and microbial growth.

The hydrogen sensor allows dissolved H2 levels to be measured inline in real time, supporting integrated monitoring alongside other parameters such as temperature and optical density.

Hydrogen Monitoring in Thermochemical Water Splitting Cycles

Thermochemical water splitting cycles use heat-driven reactions to produce hydrogen with low global warming potential.

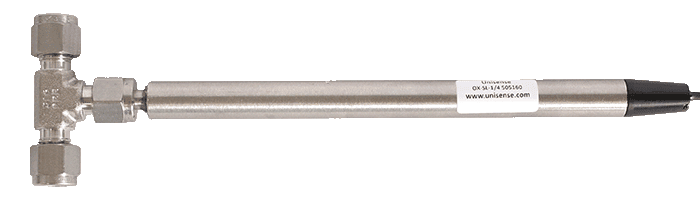

In these cyclic systems, hydrogen sensors mounted in flow cells have been used for inline hydrogen measurement during repeated production cycles.

- Real-time hydrogen monitoring enables:

- Evaluation of hydrogen yield per cycle

- Assessment of material performance and cyclability

- Identification of performance degradation over time.

Such measurements support optimization of thermochemical materials and process stability.

Real-Time Hydrogen Quantification in Small-Volume Systems

Hydrogen measurement is equally important in small-scale experimental systems.

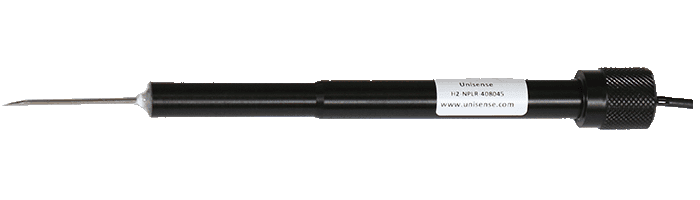

In studies of novel photoelectrodes and artificial enzyme systems, hydrogen sensors have been inserted into closed cuvettes to measure modest hydrogen production during illumination or electrochemical stimulation.

- These experiments demonstrated:

- Continuous hydrogen monitoring

- Ultrasensitive detection in small volumes

- Real-time quantification of hydrogen evolution.

Such capability is critical when hydrogen production levels are modest and precise quantification is required to validate catalyst or enzyme performance.

Advantages of Sensor-Based Hydrogen Measurement

The electrochemical measuring principle of the hydrogen sensor provides several advantages in reactor and renewable energy applications:

- Measurement in both gas and liquid phase

- Fast response time

- Ultrasensitive detection

- Flow-independent measurement in liquid systems

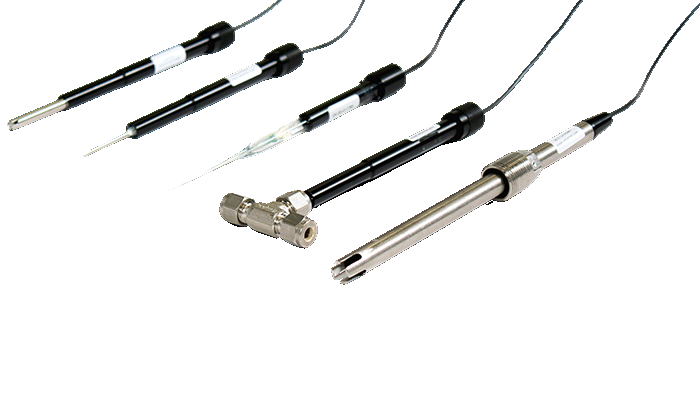

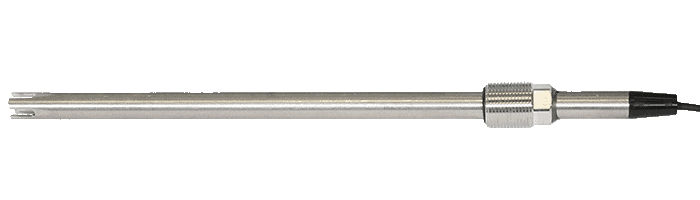

- Multiple mounting options

- Inline and in situ capability

- Suitability for high-pressure systems

- Cost-effective alternative to GC

The ability to use multiple sensors simultaneously enables spatial profiling and deeper insight into process dynamics.

Integrating Hydrogen Measurement into Reactor Systems

Hydrogen sensors can be customized and mounted in different configurations to fit specific experimental or reactor setups.

Mounting options include integration into:

- Flow cells

- Bioreactors

- Custom reactor systems

- Swagelok fittings

- Closed cuvettes

This flexibility supports both laboratory-scale research and industrial R&D environments requiring inline hydrogen monitoring.

For detailed technical information about the Clark-type hydrogen sensor and its specifications, see the hydrogen sensor product page.